What is forming fabric?

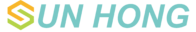

The forming fabric is an important piece of equipment for paper making machinery. It carries the forming, dewatering and transportation of paper and is used in the forming section of the paper machine. It plays a key role in the quality of paper and the stable operation of paper machines.

What are the characteristics of forming fabric? What are the categories?

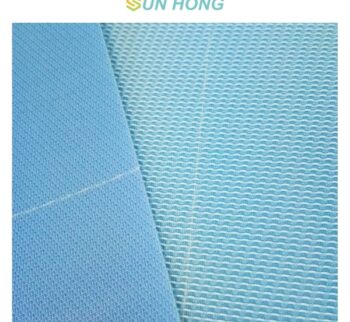

The forming fabric should have the characteristics of good dehydration, wear resistance, long operating life, and good material retention.

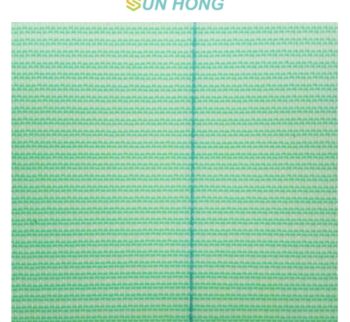

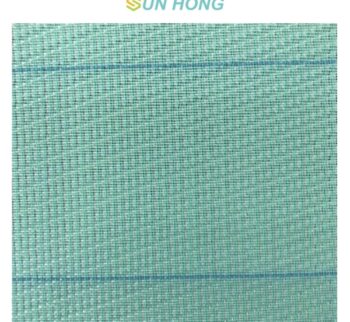

There are many styles of forming fabric, and each style has different advantages in terms of durability, fiber support, and dewatering efficiency. According to the structure, it can be divided into: single layer forming fabric, 1.5 layer forming fabric, double layer forming fabric, 2.5 layer forming fabric and triple layer forming fabric (SSB forming fabric).

How to choose forming fabric?

(1) Single layer forming fabric is mainly used to produce various kraft papers, writing papers, printing papers, tissue papers, etc., and is suitable for various paper machines.

(2) The 1.5 layer forming fabric has better dewatering performance and is often used to produce writing paper, kraft paper and printing paper. It is suitable for paper machines with machine speeds ≤500m/min.

(3) Double layer forming fabric and 2.5 layer forming fabric are the main forming fabric used in the market. Among them, the 2.5 layer forming fabric has more wear resistance and service life. It can produce various grades of paper and is suitable for paper machines with machine speed ≤800m/min

(4) The triple layer forming fabric (SSB forming fabric) has better dehydration, high paper quality, more stable operation, and longer service life. It is used to produce various grades of paper and is widely used in high-speed paper machines.

What else should you pay attention to when choosing a forming fabric?

The selection of the forming fabric model needs to be determined based on the characteristics of the paper machine and the type of paper produced. While taking into account the performance of the slurry, you also need to pay attention to the fillers and rubber materials.. The selected forming fabric should have light mesh marks, smooth and delicate paper surface, and excellent dewatering performance.

Correct use of the forming fabric requires careful selection of the length of the net. Due to the characteristics of the polyester material, the forming fabric will stretch under force. The amplitude will vary depending on the molecular weight of the material, the weaving method and the degree of heat setting. The elongation of a single layer forming fabric is generally greater than that of a multi layer forming fabric, and the elongation of a low molecular weight is greater than that of a high molecular weight. The maximum elongation will not be greater than 1.3%, the minimum will not be less than 0.3%. The maximum elongation rate of the forming fabric during operation is about 1%. Due to the high elasticity of the forming fabric, it will stretch at the beginning of use, and then the elongation will become smaller. The length of the forming fabric that starts running The best elongation is 0.5%.

In order to ensure the normal use of the forming fabric, it is very important to determine the minimum length and maximum operation of the mesh loop. Generally speaking, the length of the polyester forming fabric should be as short as possible and can be put on the paper machine. However, the length of the forming fabric needs to be finally confirmed through actual measurement.

The selection of the width of the forming fabric is determined by the paper machine model and production paper specifications. It is necessary to ensure that the wet paper meets the shrinkage range under process conditions, and pay attention to factors such as wet paper edges and burrs. It should also be noted that if the edge of the forming fabric is off-line, it needs to be heat-sealed in time to prevent the off-line from seriously affecting the life of the forming fabric.