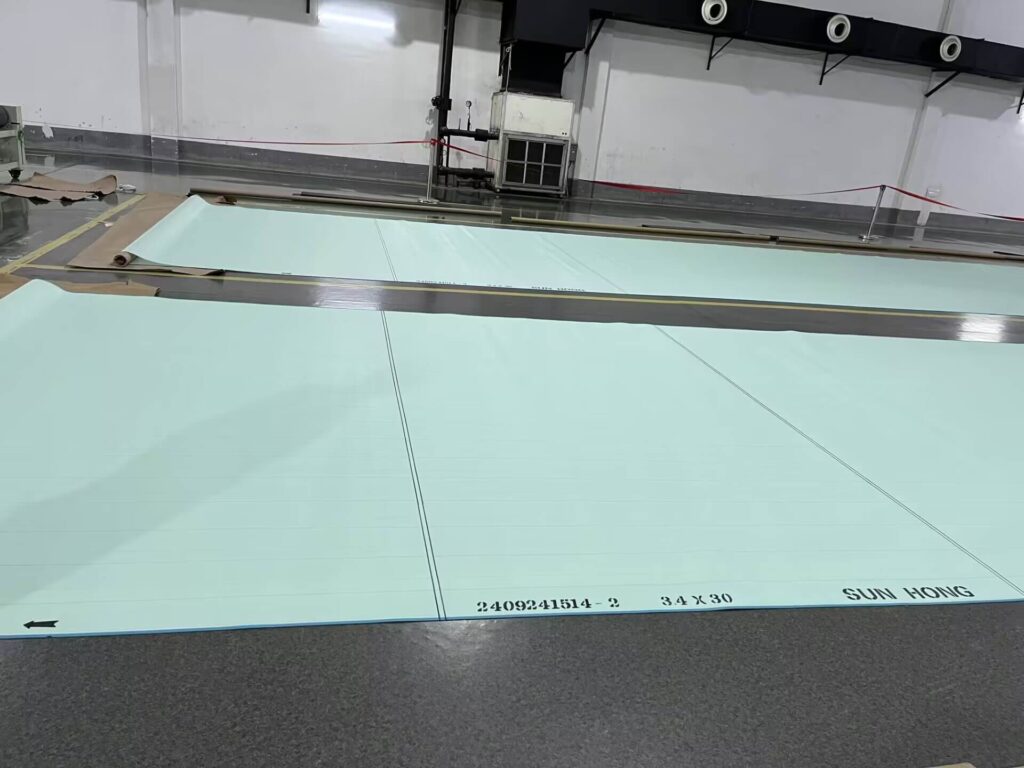

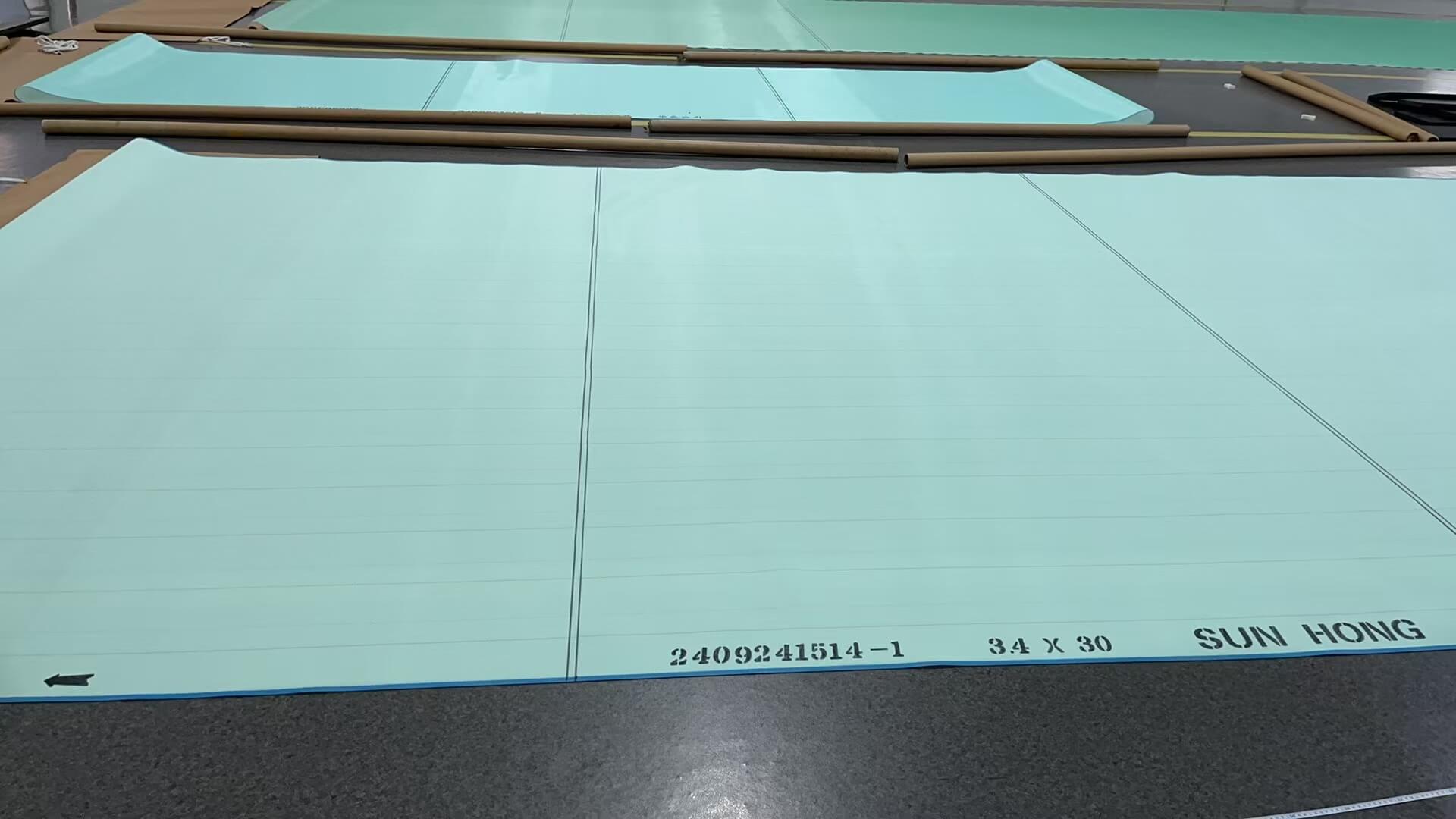

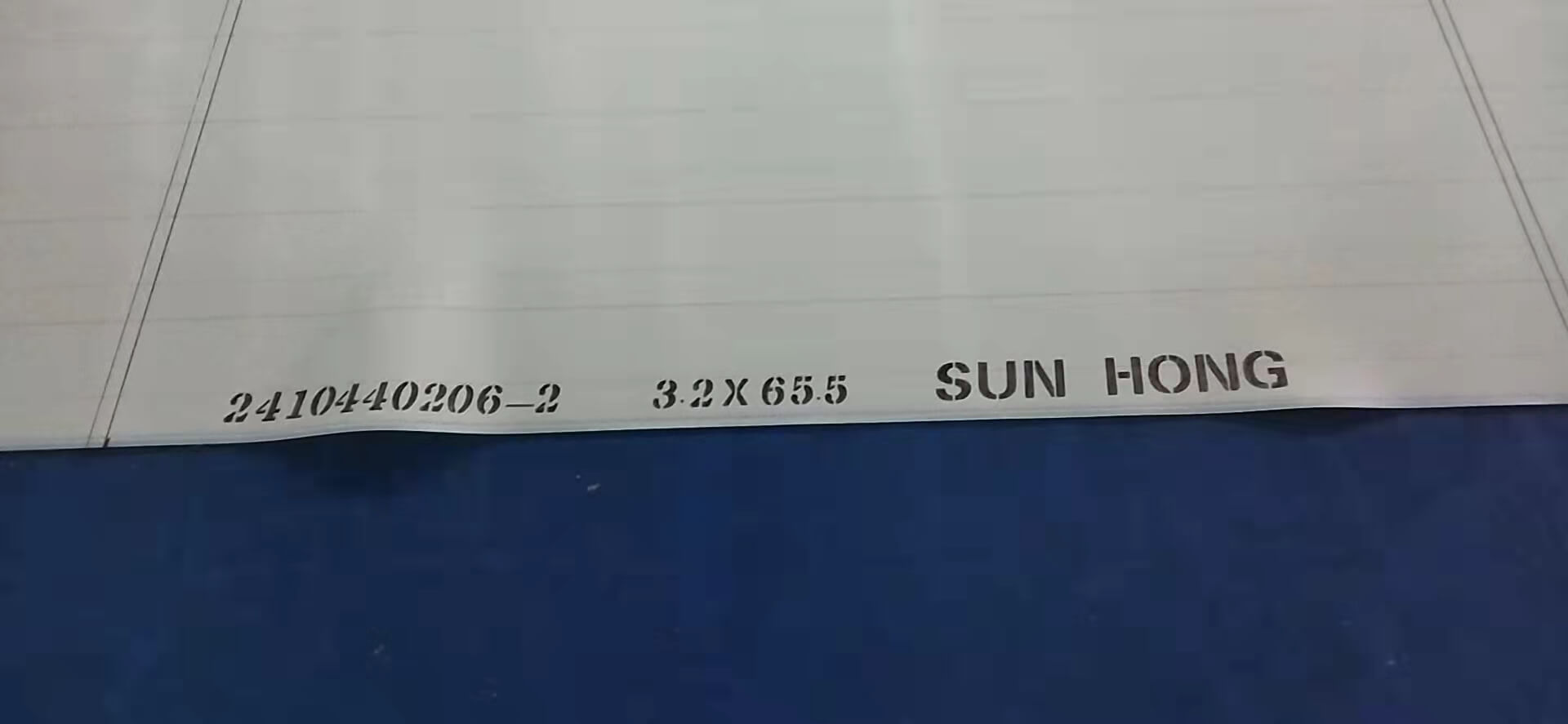

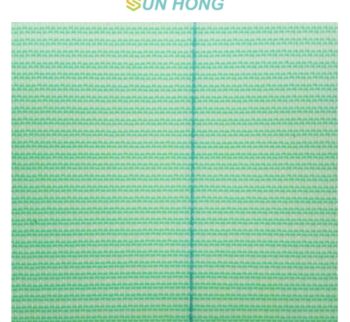

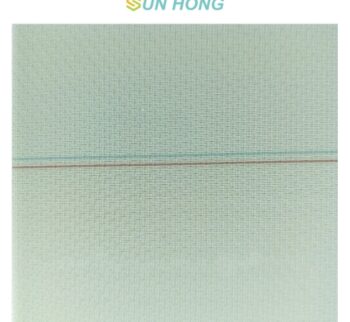

Paper Machine Clothing Forming Fabric

Product Features:

As an important equipment in the wet section of the paper machine, the forming fabric plays a huge role in the forming and dehydration of pulp. The forming fabric will support the wet paper to dehydrate and transport it to the press section of the paper machine.

One-click consultation

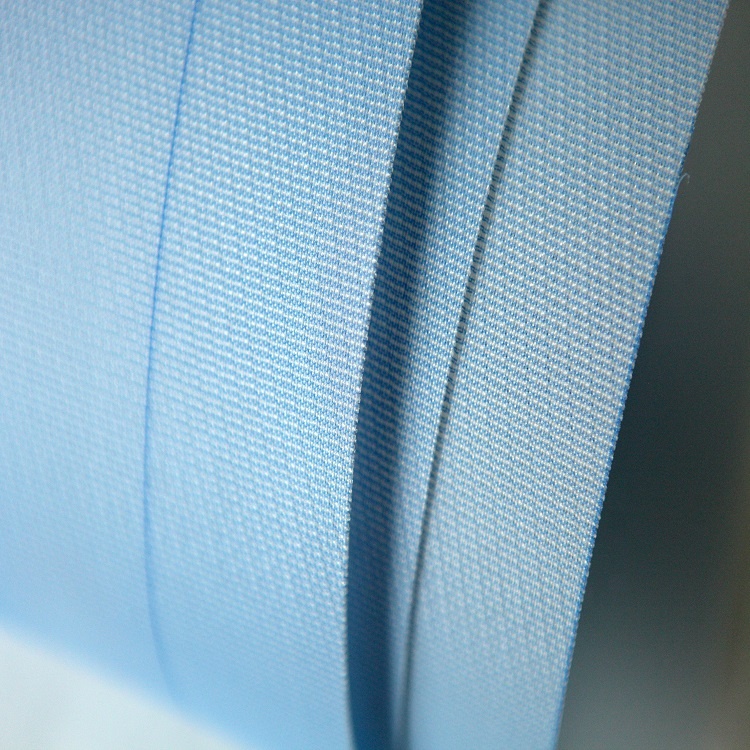

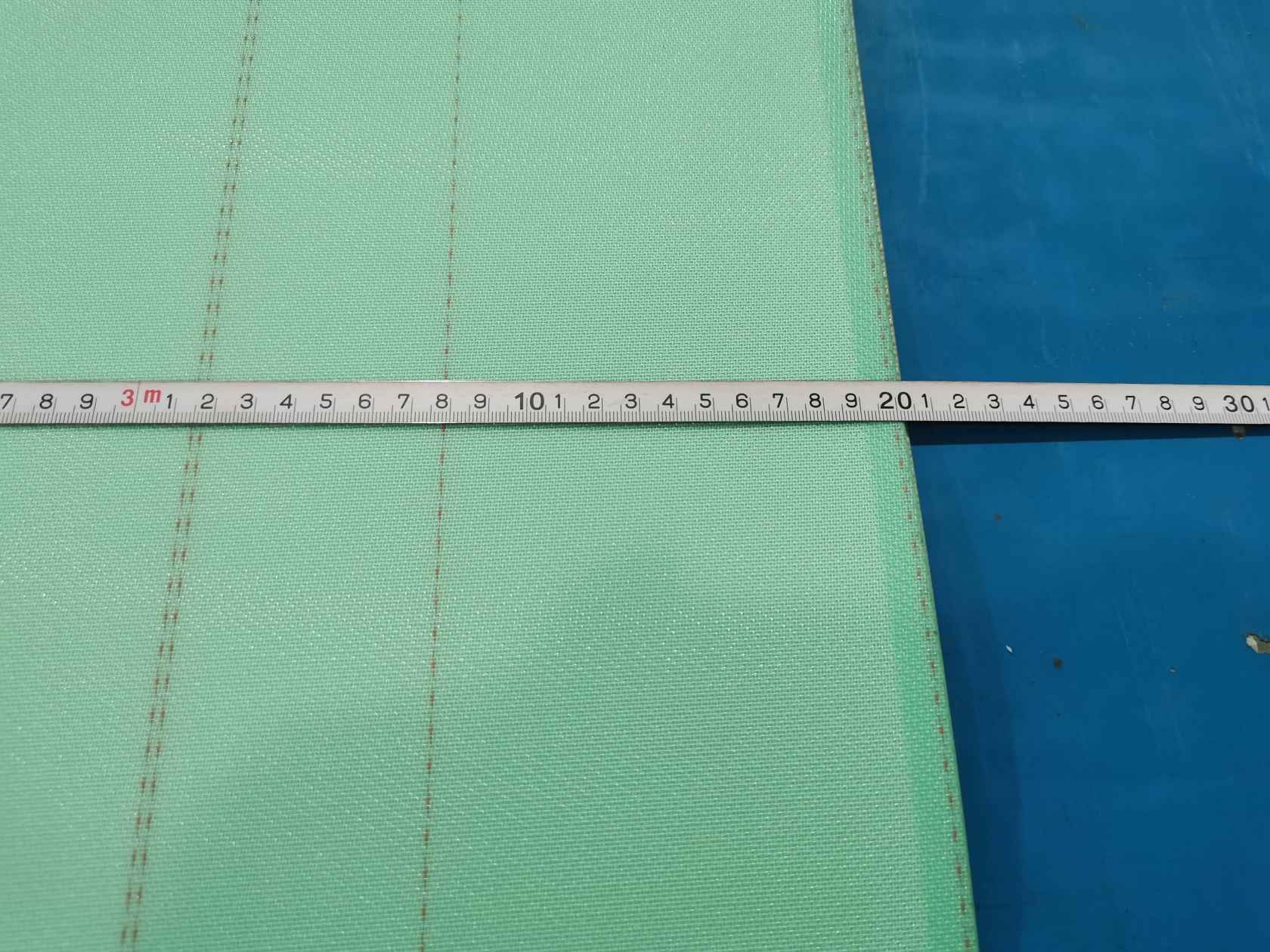

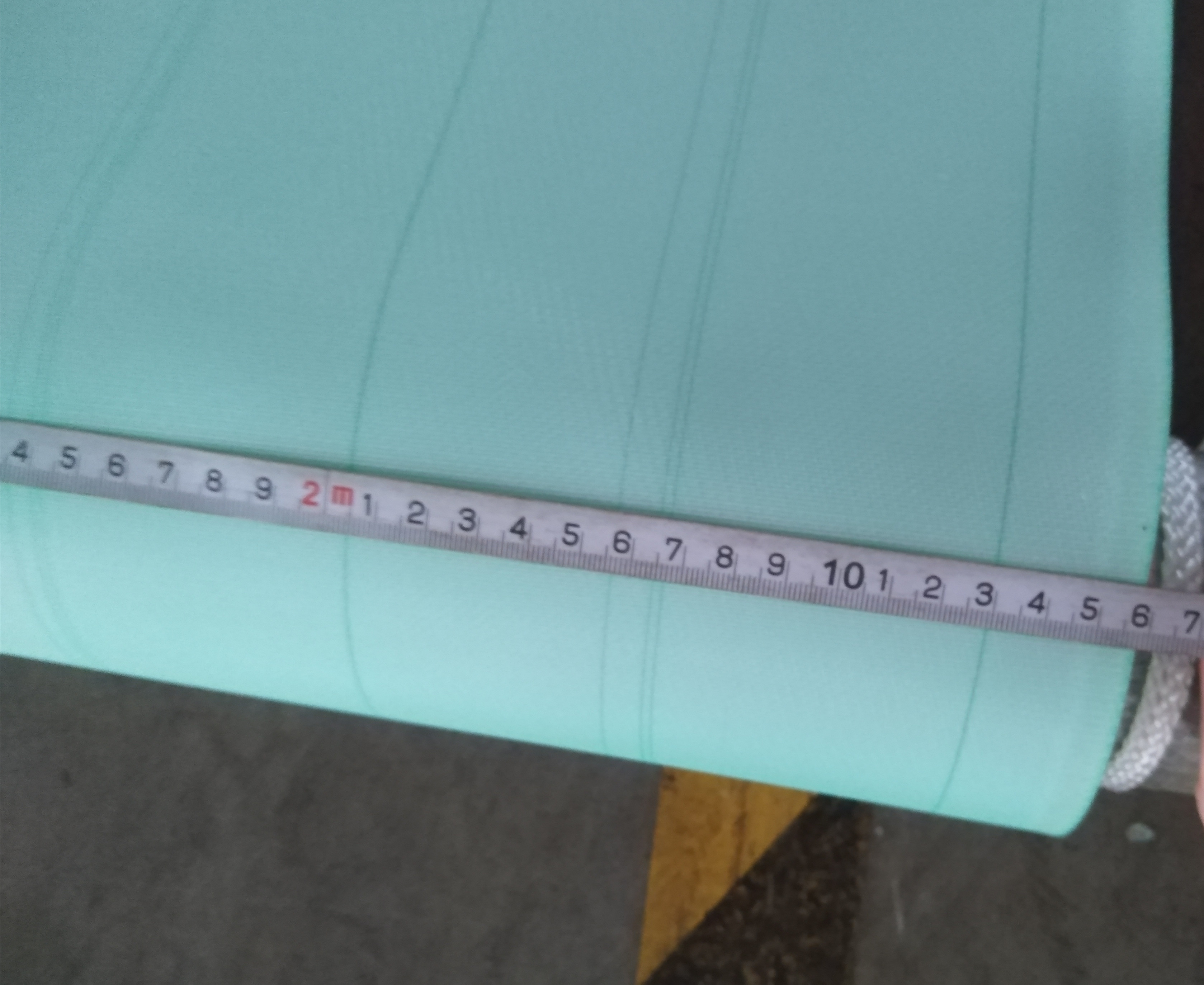

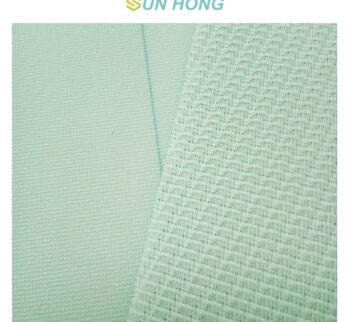

When the paper machine is running, the pulp in the headbox will flow into the forming fabric and evenly and accurately spread on the surface of the forming fabric. Then the forming fabric drives the pulp to run and dehydrate. The water in the pulp will naturally sink under the action of gravity and filter through the mesh of the forming fabric to gradually form a wet paper sheet. When passing through the vacuum water absorption box, more water will be absorbed by the vacuum device to further form the wet paper. When the wet paper is dehydrated to a certain extent, the forming fabric will transport it to the press section. Correct and good forming fabric design can produce excellent paper. In addition to having excellent strength, support, and dehydration efficiency, it must also have uniform and good mesh density and tension, and stable size, which can not only ensure the uniformity and integrity of the paper thickness, but also ensure that the fiber distribution is interwoven to form a paper with consistent thickness and a complete and smooth surface. As the simplest forming fabric, single layer forming fabric can be divided into 4 shed, 5 shed and 8 shed. 4 shelf has good tensile strength and wear resistance, suitable for producing cultural paper, packaging paper and printing paper. 5 shelf is more conducive to fiber retention, suitable for producing cultural paper, packaging paper and sanitary paper. 8 shelf increases the wear of the back weft, which not only has a good stable structure and water filtration performance, but also is the most wear resistant among single layer forming fabric. The double layer forming fabric is 8 shelf double layer. Sun Hong uses one set of longitudinal fibers and two sets of transverse fibers. Compared with the single layer, it has better stability and paper forming characteristics, and is often used in the production of writing paper and kraft paper. The 2.5 layer forming fabric is 16 shed. Sun Hong uses two additional transverse fibers to make it without changing its dehydration performance and increase fiber retention and wear resistance, making the 2.5 layer forming fabric more suitable for medium and high speed paper machines to produce high grade paper. The triple layer forming fabric is 24 shed. Sun Hong adopts a triple layer structural weaving design. The upper layer warp and weft are thinner and the lower layer is thicker. Pairs of wefts are used in the middle to connect the upper and lower layers. The triple layer forming fabric has the best paper forming quality, excellent fiber retention index and dehydration efficiency, double warp locking structure, resistance to high longitudinal load, and resistance to horizontal wrinkles. An excellent forming fabric needs to have the following characteristics, which will not only affect the dehydration effect of paper making but also the quality of paper making (1) Excellent dehydration performance: As one of the core functions of the forming fabric, it needs to filter out moisture quickly and neatly (2) Good forming quality: The forming quality will affect the uniformity and stability of the fiber, effectively reduce the foaming and wrinkling problems of the paper and improve the appearance quality (3) With excellent edge life, Sun Hong uses the glue edge formed by the glue edge machine imported from Germany to penetrate the mesh. The strong adhesion perfectly solves the edge wear problem of the forming fabric and prolongs the service life. (4) Anti blocking, using a special mesh design to effectively reduce the adhesion of fibers and impurities, easy to clean, keep the mesh surface unobstructed to ensure the dehydration effect As a paper machine clothing supplier, Sun Hong can provide forming fabric of various specifications (single layer forming fabric, 1.5 layer forming fabric, double layer forming fabric, SSB triple layer forming fabric). It adopts imported machinery such as Swedish TEXO warping machine and rapier loom, Norwegian 12.5 meter shaping machine, and fully automatic splicing machine to accurately control the production process of forming fabrics, with high processing precision, small tension error (the tension error of each single filament is within 5%), high speed and stable temperature error, and fast splicing while ensuring the quality of the interface. Operation mode of the forming fabric in the paper machine

Operation mode of the forming fabric in the paper machineThe structure and application of forming fabric

Features of forming fabric