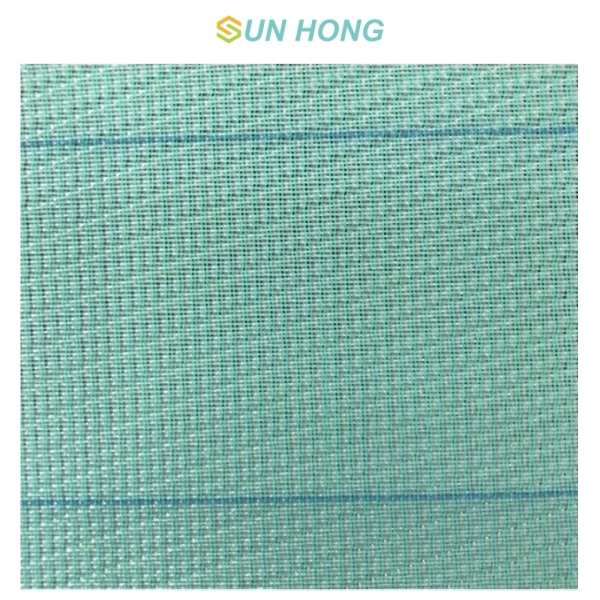

Single Layer Forming Fabric for Paper Making

Product Features:

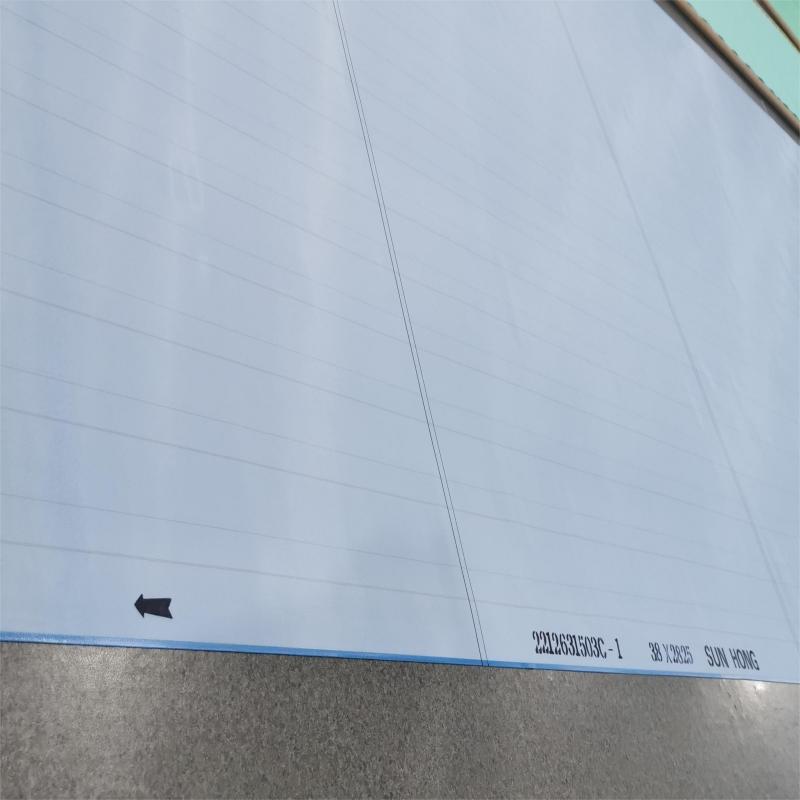

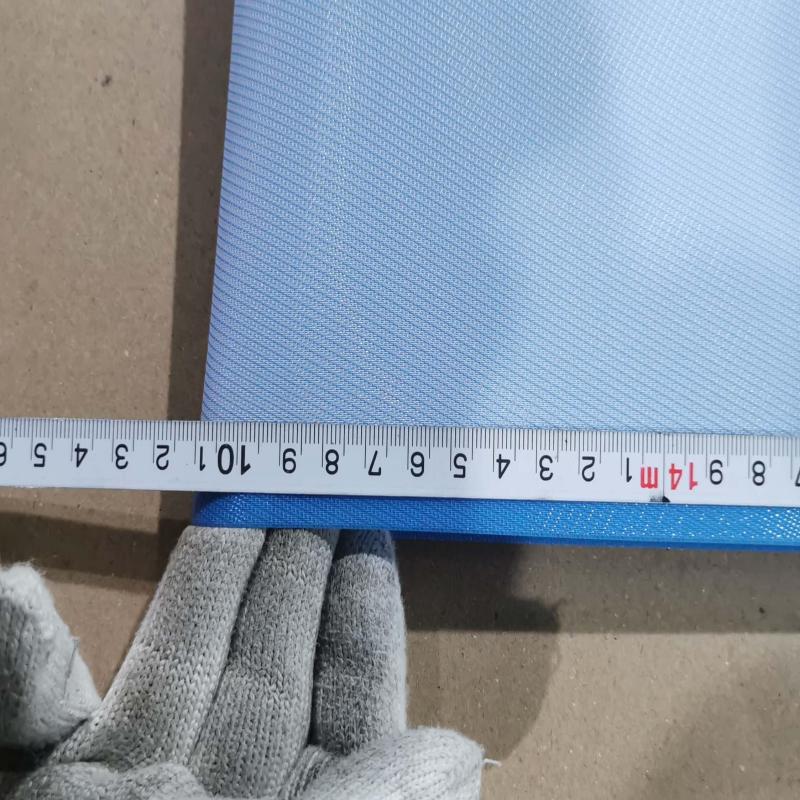

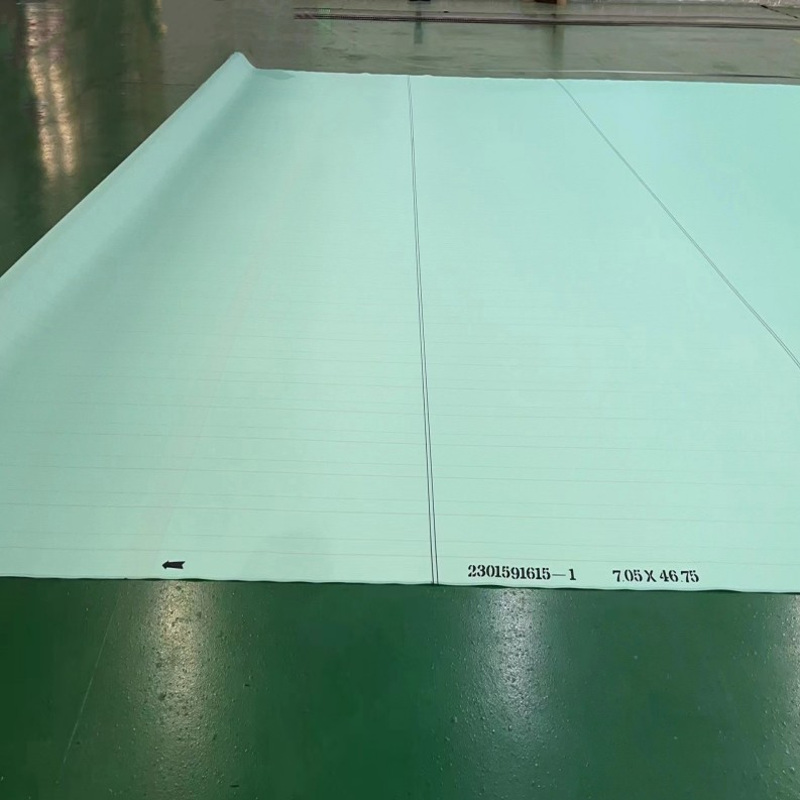

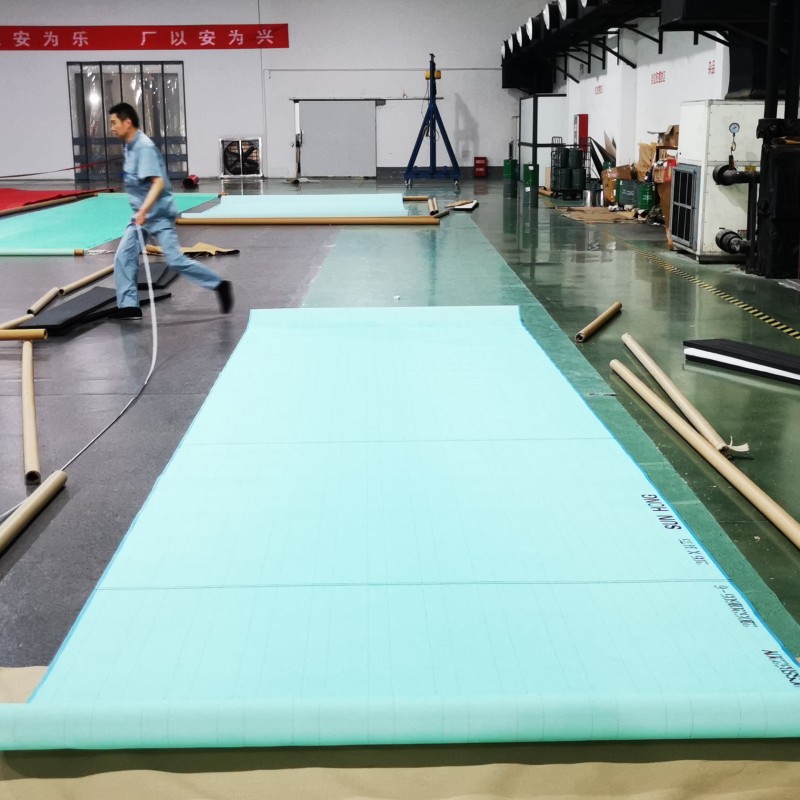

Forming fabric is an indispensable equipment in the paper making industry. It is used for forming, dehydrating and transporting paper. A well designed forming fabric needs to have good stability and efficient water filtration performance. Sun Hong has more than ten years of experience in forming fabric production, using advanced production equipment imported from foreign countries (14m German looms to ensure high quality and large width. Equipped with Austrian automatic splicing machines to ensure uniform and stable splicing). Its glue edge adopts a special design, and reinforcing ribs are added to the edge of the net, so the glue edge has strong adhesion.

One-click consultation

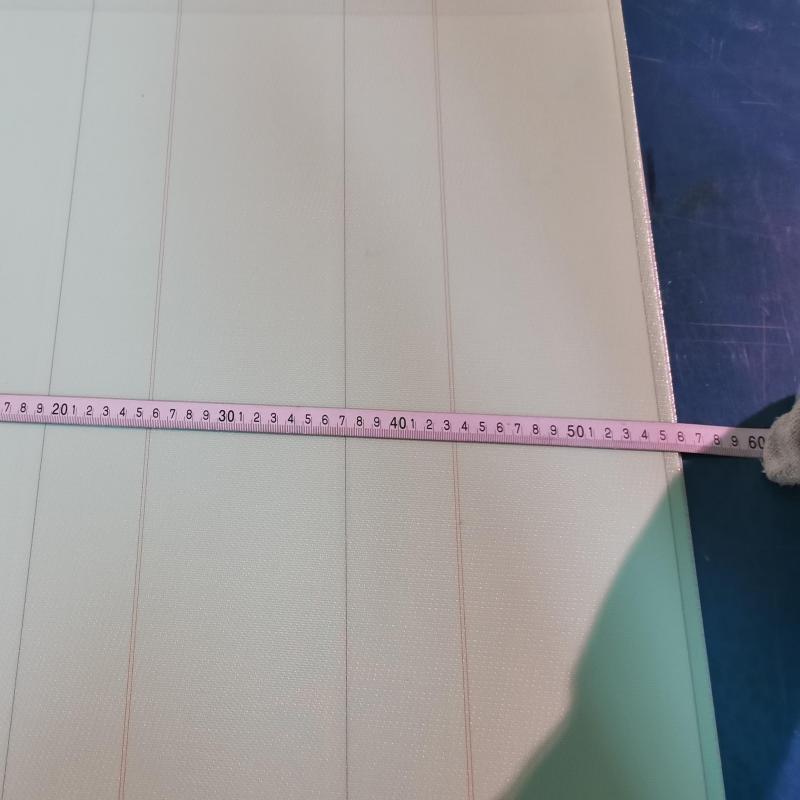

The forming fabric is an important part of the paper machine forming section. Its operation process determines the quality and production efficiency of paper forming. The headbox transports the pulp to the forming fabric, providing the necessary prerequisite for the good forming of the paper web. The forming fabric carries the pulp while running at high speed, evenly distributes the fibers on the wire surface, and forms a preliminary paper structure. Then, the forming fabric quickly absorbs the moisture in the pulp under the action of the vacuum water absorption device and gravity, maintaining the stable distribution of fibers. As the forming fabric runs, the pulp is gradually dehydrated to form a wet paper sheet, laying the foundation for subsequent pressing and drying. According to the weaving, single layer forming fabric can be divided into 4 shed, 5 shed and 8 shed single layer forming fabric. The single layer forming fabric designed with 4 shed can provide better dehydration and stretch ability. Suitable for various paper machines, suitable for making cultural paper, printing paper, packaging paper, etc. The single layer forming fabric designed with 5 shed has better stretch ability and dehydration than 4 shed and is suitable for the production of various kraft paper, tissue paper, printing paper and other paper making equipment that require a high degree of dehydration. The single layer forming fabric designed with 8 shed can provide better dehydration and stretch ability. Suitable for various paper machines, suitable for making cultural paper, printing paper, packaging paper, etc. Since polyester materials have a strong affinity for foreign matter, tiny particles and fine fibers can easily adhere to the forming fabric. Here are some precautions for cleaning low and medium speed paper machinesWhat is a forming fabric?

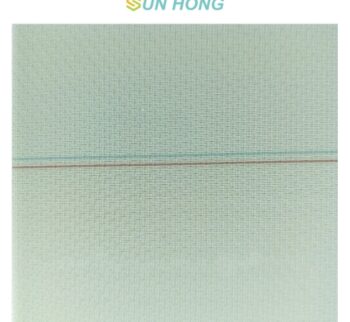

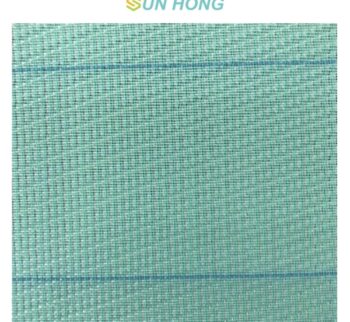

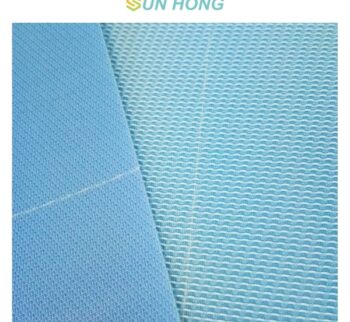

Single layer forming fabric structure

Single layer forming fabric

Weaving Series and Types

Model

Filament Diameter (mm)

Density(root/cm)

Tensile Strength

Thickness

m³/m2h

Force elongation

(mm)

Warp

Weft

Warp

Weft

Surface

Joint

4 heddle

SH27254

0.2

0.25

30

22

≥600

≥400

0.49

8000

0.60%

SH27274

0.2

0.27

30

21.5

≥600

≥400

0.51

7800

0.60%

SH31204

0.18

0.2

35

28

≥600

≥380

0.43

7500

0.68%

SH31204-1

0.18

0.2

35

30

≥600

≥380

0.43

7000

0.68%

5 heddle

SH30205

0.17

0.2

32

28.5

≥500

≥350

0.41

7100

0.60%

SH31215

0.2

0.21

35

32

≥600

≥400

0.48

7000

0.60%

8 heddle

SH25358

0.22

0.35

28

19.5

≥700

≥500

0.85

9000

0.65%

SH25388

0.22

0.38

29.5

19

≥700

≥500

0.87

8500

0.65%

SH27358

0.22

0.35

30

20

≥700

≥500

0.85

8500

0.65%

SH25458

0.22

0.45

29

15.2

≥700

≥500

0.87

7500

0.65%

Maintenance of the forming fabric

(1) Low pressure water chemical cleaning of low and medium speed paper machines: If a low speed paper machine cannot be installed with a high pressure cleaning system due to production conditions, it should be flushed with low pressure water. Use 0.4~0.6Mpa clean water with detergent, hydrochloric acid, banana water, etc. for flushing. Nylon brushes are more effective for cleaning severely blocked holes.

(2) If a low and medium speed paper machine does not have a high pressure cleaning system and is not suitable for chemical cleaning, it can be cleaned with low pressure water and auxiliary high pressure water guns (high pressure water guns can be 4.0-5.0Mpa). Do not aim at one position when cleaning, just swing and flush 20-40cm away from the forming fabric.