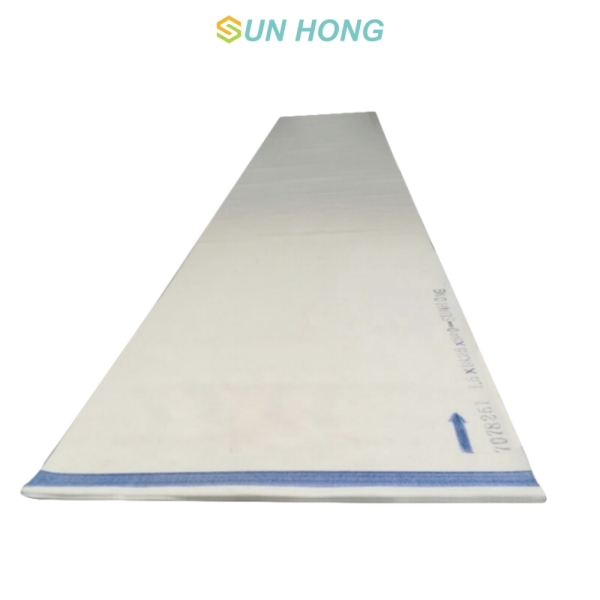

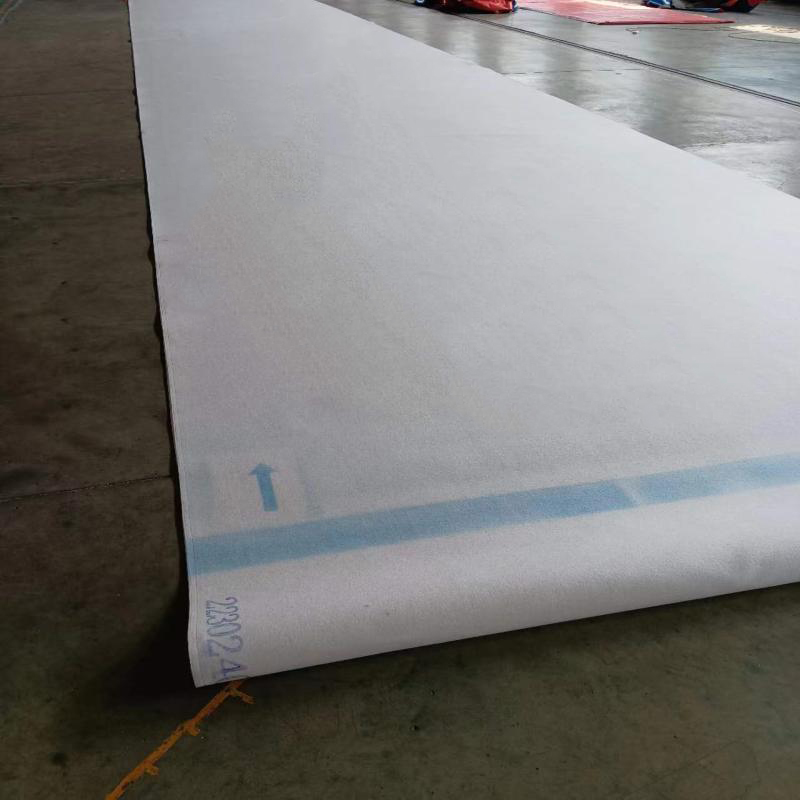

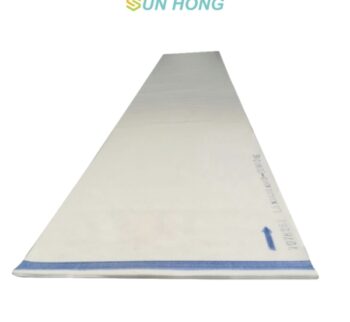

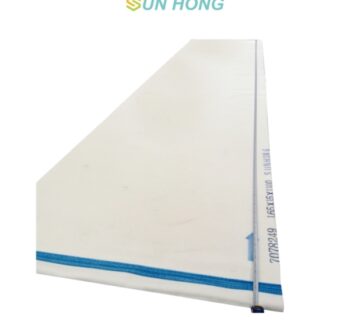

Paper Making Pick Up Felt

Product Features:

The surface of the paper produced by the pick up felt has no holes, pinholes, uniform paper quality and good texture, which makes our products very competitive in the market. Pick up Felt:

One-click consultation

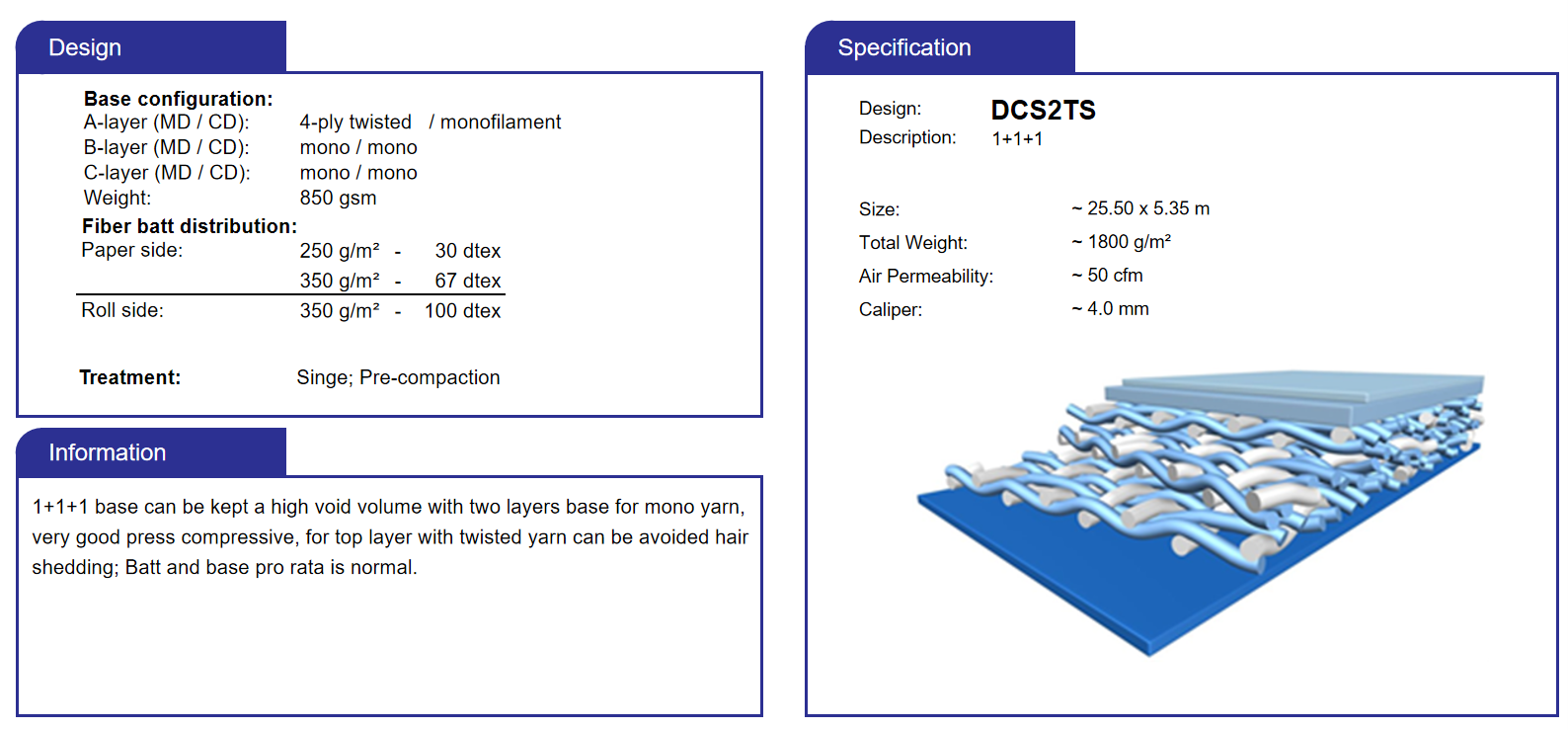

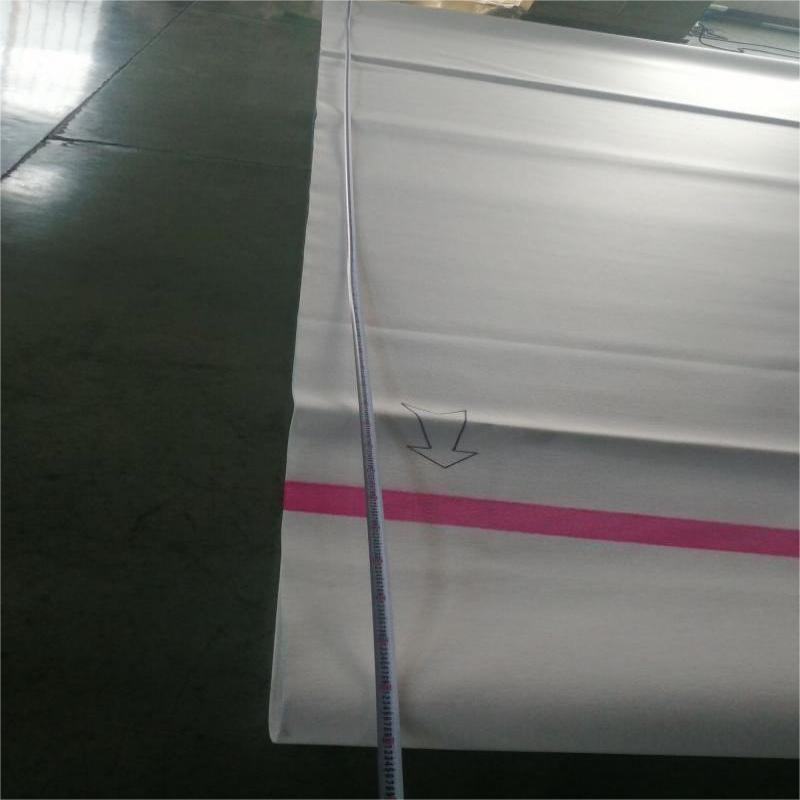

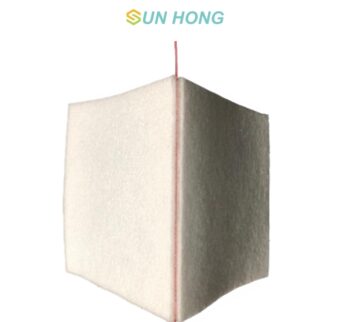

Structure of BOM Felts BOM felts is composed of backing layer and fiber layer. The bottom net layer adopts monofilament and mono and multifilament combined strand chemical fiber materials, using different weaving techniques to make single-layer, double-layer, multi-layer, stacked (1 +1, 1 + 2, 2 + 2 ┄) and other organizational structure of the endless fabrics; fiber layer of the commonly used synthetic fibers are mainly nylon staple fibers, polyester staple fibers and other raw materials, etc.; will be the same or different thicknesses of staple fibers in the bottom of the net laying, and the bottom net layer and the fiber layer after the Needle punching, heat-setting and other special post-finishing treatment and other production processes made of BOM felts. Pick up Felts As one of the important equipment in the wet section of the paper machine, pick up felt will transport the wet paper to the press section for further dehydration. Pick up felt has good water absorption, softness and wear resistance to ensure effective transmission while maintaining the integrity and uniformity of the paper. Endless press felt and seamed press felt is commonly used in current paper mills. Sun Hong can provide more suitable fabric and felt according to the needs of paper machines, and customize professional paper machine clothing integrated solutions for you.

In the forming stage, the pulp passes through the forming fabric to form wet paper. Pick up felt uses its high adsorption and softness to contact the wet paper and transport it to the press section. Sun Hong uses advanced TEXO looms to weave the bottom net, making the bottom net more stable and elastic, and covers it with synthetic fibers and wool combing to improve the surface flatness, so that the pick up felt can ensure that the wet paper does not move, wrinkle or break during transportation to the press section. In addition, the good water absorption of the pick up felt during transportation can effectively remove part of the moisture in the wet paper, reduce the subsequent dehydration pressure, and help improve the tightness and quality of the paper and enhance the efficiency of the press section.