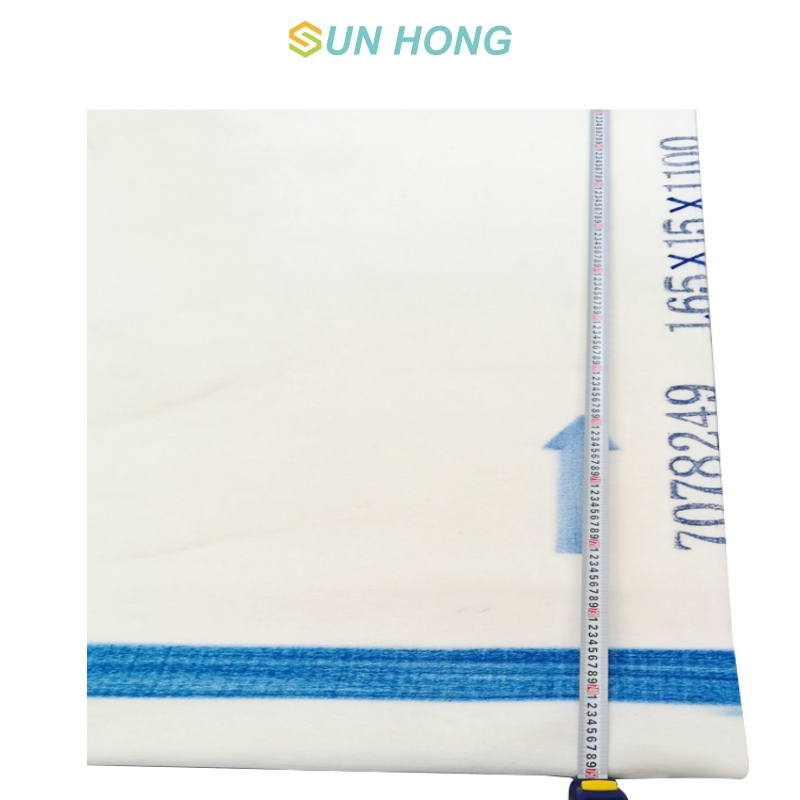

Paper Machine Clothing Press Felt

Product Features:

The paper making press felt is composed of nylon and polyester. It is a fabric used for press and dehydration on the paper machine. The press felt will dewater, press, shape and dry the paper when the paper machine is running.

One-click consultation

Paper Machine Felts Press felt the base fabric is made of synthetic fibers, covered with a mixed fiber mesh of synthetic fibers and a little wool, and then made by needling, shaping, cutting and edge sealing, used For paper forming, press dewatering and transport. press felt can be divided into single layer, double layer and triple layer BOM press felt. Sun Hong has single layer BOM press felt、Double layer BOM press felt and triple layer BOM press felt to meet your needs. Single Layer Felts The single layer basepaper-machine felt consists of a single layer backing layer and a fiber layer. The backing layer is made of nylon monofilament or monofilament combined warp and weft yarns. The organization structure is set according to different paper machines, different parts of use and different paper grades. The fiber layer is made of chemical fibers of different thicknesses and layered. It is characterized by good water filtration, small elongation, easy washing, light felt marks, effective reduction of groove marks and long service life. Single layer felts are usually used in low and medium speed paper machines with a speed of 800m/min or less, and are mainly used for the production of packaging paper, cultural paper, household paper and specialty paper, etc., with a felt weight range of 700-1200gsm. Double Layer Felts The double bottom mesh felts include 1+1 composite structure and double bottom mesh felts. The 1+1 composite structure bottom mesh is made of two different thicknesses of bottom mesh stacked together, according to the requirements of the paper machine and paper type, the thickness of the upper and lower bottom mesh can be changed at will. The double bottom net paper making felt has good elasticity against high line pressure, good water filtration performance, stable size, small elongation, high strength, and can effectively eliminate vacuum marks, groove marks, blind hole marks and other marks. It is suitable for groove press, vacuum press, various kinds of composite press, large roll diameter press and other press types. It is used for copying high-grade cultural paper, newsprint, scientific and technological paper, various packaging paper, high grade board (card) paper, and so on. The speed is below 800m/min, and the felts weight range is 700-1200gsm. Triple Layer Felts Stacked base net paper felts are usually divided into 2+1, 1+2, 1+1+1, etc. The structure of base net stacking can be the same or different, and the combination and matching forms are flexible, which can satisfy the press types such as vacuum press, composite press, large roll diameter press, boot press, etc., and can be used to copy all kinds of paper grades such as wrapping paper, cultural paper and specialty paper. The structure of base net and base net can be the same or different, and the combination and matching forms are flexible, which can meet the press type of vacuum press, compound press, large roll diameter press, boot press, etc., and can be used to copy all kinds of paper grades, such as packaging paper, cultural paper and special paper. The laminated felts can resist pressure up to 1000kn/m, the working speed is 300-1000mpm, and the weight range of the blankets is 1200-1900 gsm. It has the features of stable structure, superior compression resistance, strong sustained dewatering ability, high strength, flat surface, not easy to be deformed, and long service life.

Each product will undergo strict quality inspection before delivery to ensure that customers have a good experience.Sun Hong Press Felt Series