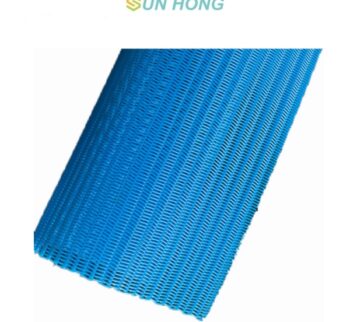

Corrugated Paper Conveyor Belt

Product Features:

One-click consultation

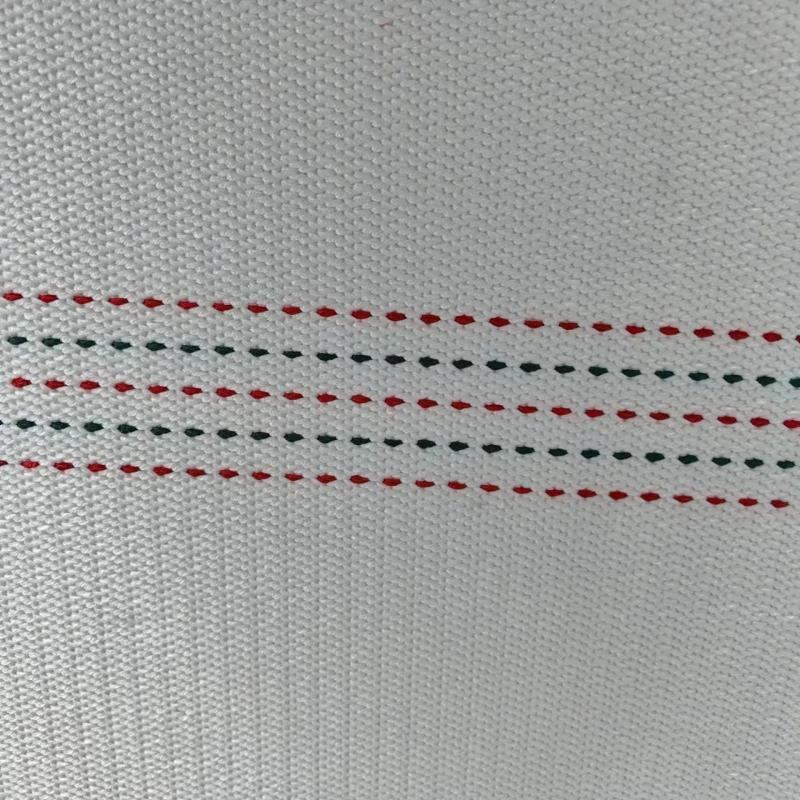

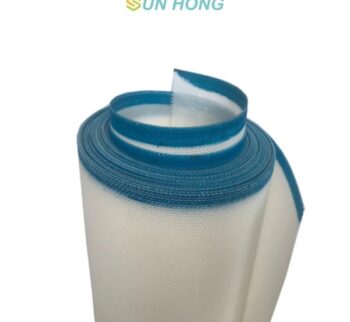

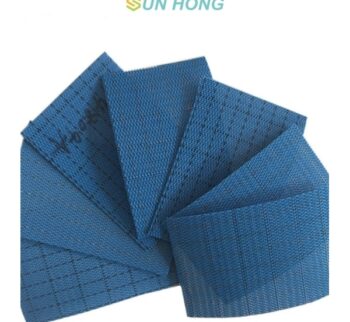

It is an important equipment of corrugated cardboard production line and plays a decisive role in the quality of corrugated cardboard. There are two types of conveyor belts located in the drying section of the production line: one is cotton woven belt; The other type is acupuncture tape. SUNHONG corruagtor belt is suitable for corrugated board production line and specially developed for double-sided machines. The four functions of the conveyor are smooth cardboard transport, straight line operation, uniform distribution of pressure in the system pressure to ensure the best hot plate and cardboard drying.Specially developed for transporting paperboard and optimizing the drying process, corrugated strips are able to sustain pressure resistance and extend service life as much as possible.The patented braided structure ensures the correct bonding and quick drying of the board.The use of high quality PET fibers allows the belt to quickly remove moisture absorption during the drying process. Corrugated board conveyor belt is undoubtedly one of the most important parts of corrugated board production line. Its quality has a decisive impact on the quality of corrugated board, and has always been the concern of carton factory and tile line manufacturer. In terms of structure, there are two kinds of conveyor belts used by corrugated board production line leaders: one is cotton woven belt, which is made of multi-layer cotton yarn and chemical fiber blended and woven by weaving machine, which has the disadvantages of large weight per unit area, uneven surface and large friction coefficient; the other is needle prick belt, which is made of polyester fiber and artificial cotton as basic raw materials and processed by multiple processes of needle punching machine It has many advantages, such as smooth surface, uniform thickness, no indentation and so on.