What is a paper making press felt?

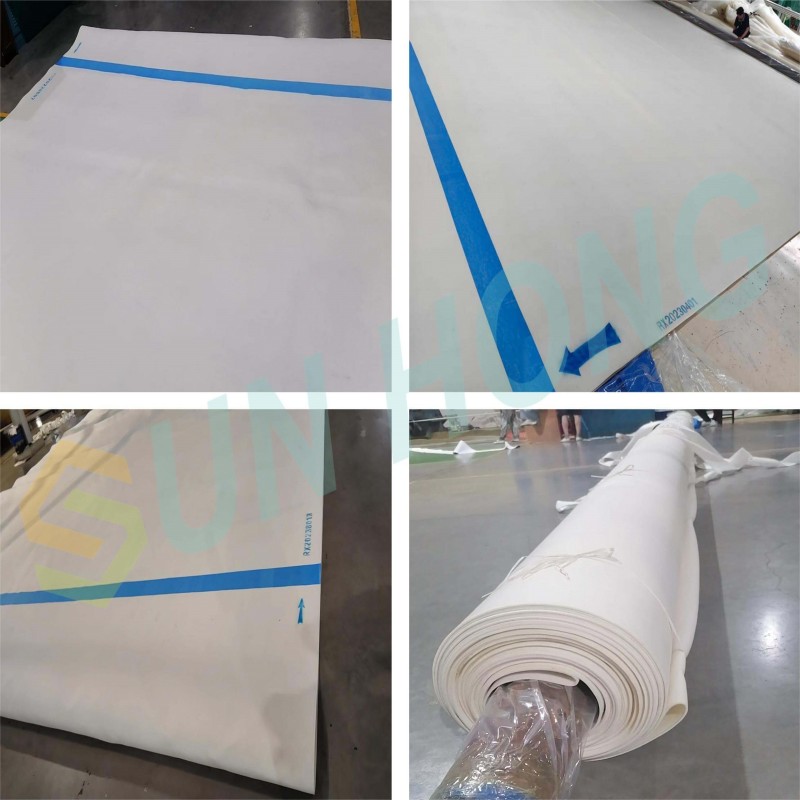

As a dehydration and transportation equipment on the paper machine, the paper making press felt plays a role in filtering the moisture of the pulp and transporting it on the paper machine. Therefore, the paper making felt is required to have good dehydration and wear resistance. It is made from the processes of base net preparation, wool net preparation, base net shaping, acupuncture, finished product shaping, edge cutting and edge sealing.

What are the considerations when choosing a press felt?

At present, all-chemical fiber needle-punched press felt is basically used in China. Needle-punched press felt have the characteristics of high dehydration efficiency and no singeing.If the vehicle speed is not high, the weight should be 730 to 750 grams, and the weight of the top press felt needs to be 50 grams more, which needs to be determined based on the press felt structure, pressure, dryer cylinder etc size.

Also note that there are two sides of the press felt, and each side is different. The front side has an arrow mark and the fibers are delicate and soft to the touch, while the back side has slightly harder fibers and rough shaping points.

How to install press felt? What needs to be paid attention to?

When installing the press felt, The sizing surface of a press felt, and the running direction should be according to the direction of the arrow on the blanket. Pay attention to

keeping the blanket clean to avoid being stained with oil. After the installation is completed, you can use 50°C~60°C hot water, add 5%~10% sodium hydroxide or detergent, and then idle for about 20 minutes to clean, and then idle for 2~3 hours until the press felt is soft.

In the early stage of using the press felt, the tension can be moderate but not too tight, and the vehicle speed can be moderate. After 2 to 3 days, increase the vehicle speed and tighten the press felt. This will facilitate the initial adaptability of the press felt and extend its service life.

How to use press felt correctly?

When putting the new press felt on the machine, keep the speed between 70 and 80, and drive slowly for 2 to 3 hours. After 24 hours, increase the speed to 90~100, and after 36 hours, increase it to 100~130, then run it to full speed, and clean it once after a week of use.