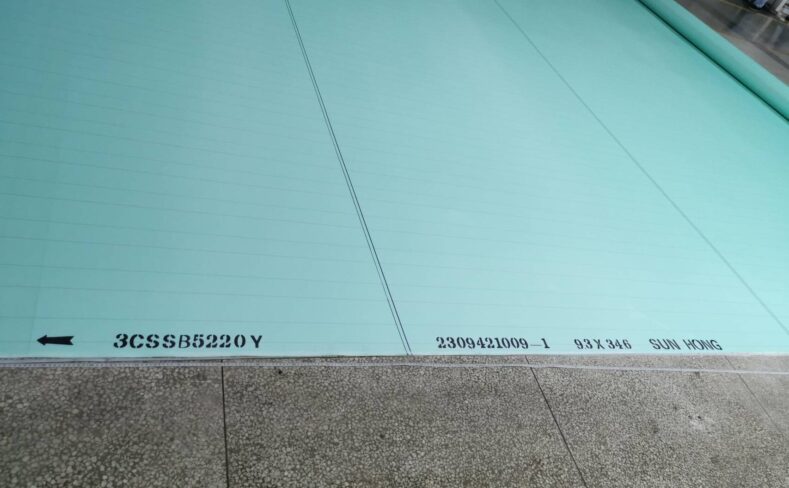

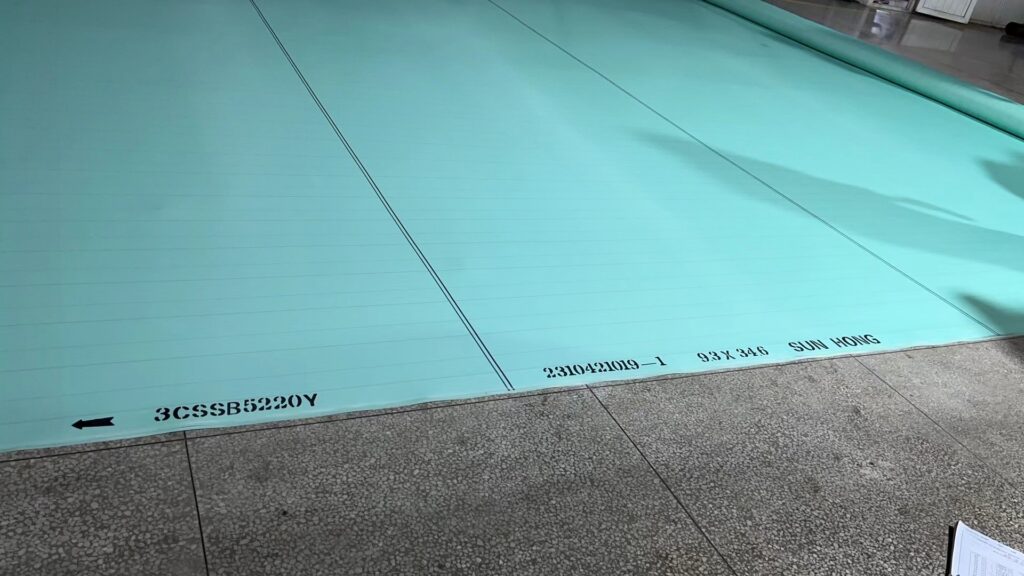

The forming fabric is an important piece of equipment on the paper machine. It is a component for forming and dehydrating the paper on the paper machine. It will dehydrate the pulp suspension from the headbox and run it to the subsequent sections.

Polyester forming fabric is a commonly used water filter in the forming part of paper machines. It is mainly woven from polyester monofilament. In order to enhance the service life of the forming fabric, manufacturers will add nylon monofilament braiding with better wear resistance at intervals in the weft. .

Extending the service life of the forming fabric is of great significance to reducing the cost of paper production. Here are some effective experiences summarized in actual operations for reference:

- All components of the Fourdrinier paper machine must be accurately aligned and in good mechanical condition;

The water filter elements must be at the same height and fastened;

Check that the tension roller and the automatic tension adjustment device cannot bounce up;

- Fillers that eliminate abrasive effects such as calcium sulfate;

- Check the net trajectory, correction, tension, load and slip;

Ensure uniform lateral tension of the paper machine;

Do not run the forming fabric in too relaxed a state;

- Keep the spray water temperature and pH value consistent with the slurry;

Make sure that the spray water pipes on both sides are not blocked;

- Use the upper surface of the vacuum suction tank with low friction coefficient;

Check whether the upper surface of the vacuum suction box is flat;

- Reduce the number of vacuum suction tanks and increase the openings;

Reduce the degree of vacuum to prevent the forming fabric from getting stuck or blocked on the vacuum suction box;

- Remove coarse sand from the slurry (centrifugal slag remover);

Check whether there are scratches and burrs on the surface of the forming plate, vacuum suction box and chopping board;

- Use net cleaner;

- There should be adequate traction to ensure that the net does not slip at the breast roller;

- Operate under the minimum vacuum of the water suction tank specified in the operating procedures;

Ensure that water flow can freely enter the water seal groove from the water suction box;

- Check the installation of the forming plate to ensure there is enough space for uniform and minimal breast roll drainage;

- Check the cleaning of the net steering roller system;

Check the scraper, scraper load, spray water, bearings and excessive spray water pressure;

- Check the wear marks on the edge fixing device or headbox cheek plate to determine whether it is installed too low;