With the development of the papermaking industry and the rapid increase in paper machine speed, there are further requirements for the dehydration of the press section. At present, the shoe press can greatly improve the dehydration effect when running on a high-speed paper machine. Compared with traditional pressing, the pressure zone of the shoe press is several times that of the traditional press, and under the same vehicle speed conditions, the residence time of the paper sheet in the shoe-shaped pressure zone is also much longer than that of the traditional pressure zone. The shoe press can obtain a higher line pressure, which is much higher than the traditional roller pressure line pressure.

Shoe pressing is to change the instantaneous dynamic dehydration of roller pressing to long-term wide pressure zone dehydration under static pressure. It is a wide pressure zone press that improves the dehydration efficiency of paper and is more conducive to paper solidification, so that the paper can obtain better strength before drying and save steam consumption, so that the press section can obtain better operating performance.

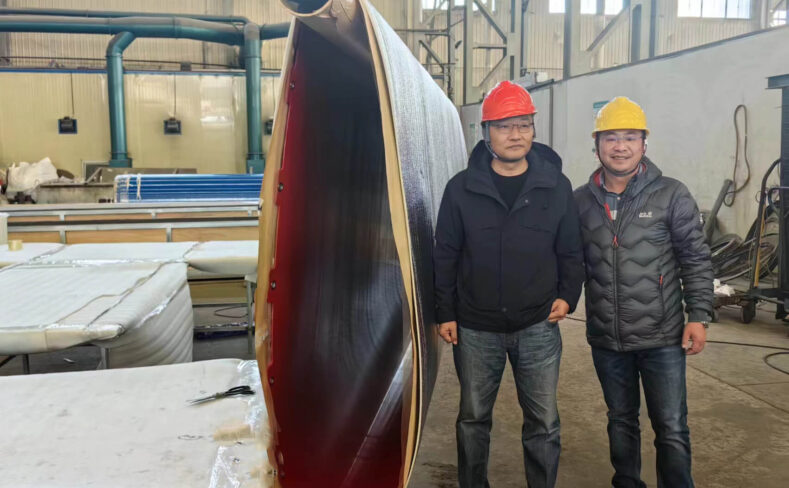

The shoe press is mainly composed of a shoe roller, a back pressure roller, a load lock and auxiliary components. The shoe roller is mainly composed of a shoe plate, a rotating head, a crossbeam, a bearing seat, etc., and the soft material on the outer cover of the shoe roller is the shoe press belt. The shoe press belt is installed on the special bearing of the roller core through the pressure plate as a rotating component. The shoe plate is the core of the shoe press. One end of it is connected to a special hydraulic cylinder and fixed on the beam inside the shoe roller. Under the action of the cylinder, the shoe plate applies pressure to the back pressure roller. The shoe roller itself has no drive device and the roller core is stationary and non rotating. The hydraulic oil is injected into the concave groove between the pressure shoe and the shoe sleeve through a special oil hole to produce a high-pressure oil film that can support, lubricate and cool the shoe plate and the shoe press belt.

Sun Hong’s shoe press belt is made of polyamide and polyurethane, with good alkali resistance, stable structure, chemical resistance and impact resistance, long service life and can greatly reduce the possibility of cracks. Sun Hong’s shoe press belt surface grooves have a variety of designs for customers to choose to further improve the dehydration performance.

Sun Hong’s shoe press belt is made of polyamide and polyurethane, with good alkali resistance, stable structure, chemical resistance and impact resistance, long service life and can greatly reduce the possibility of cracks. Sun Hong’s shoe press belt surface grooves have a variety of designs for customers to choose to further improve the dehydration performance.

The following are the reasons why the shoe press belt is damaged and cannot be used any longer:

(1) The shoe press belt is damaged due to hard objects entering.

(2) Cracks occur due to fatigue due to constant bending of the boot cover.

(3) Delamination caused by foreign objects stuck in the outside world.

(4) Severe wear caused by abnormal reasons.

For the maintenance of the shoe cover, the most important thing is cleaning. The shoe press belt is also a fragile equipment. A tiny hole is enough to be fatal.

The shoe press presses slowly and evenly. Even when producing high weight paper, it will not collapse. Compared with the roller press roll, the paper surface dryness of the shoe press is significantly improved, with good bulk and shallow press felt texture. At present, the shoe press is the most advanced dehydration technology for cardboard, packaging paper, and cultural paper. It has great advantages in changing the longitudinal pressure to independently adjust the width of the pressure zone and the line pressure.